While I was fishing at Savage River, I came across a giant chicken of the woods. I took about three pounds home to eat, which wasn’t even half.

While I was fishing at Savage River, I came across a giant chicken of the woods. I took about three pounds home to eat, which wasn’t even half.

Been a long while since I posted. I had the chance to do some fly fishing up in Western Maryland at Savage River last week. I was expecting brown trout, but the first fish I caught was a beautiful brookie in full fall colors. I took a quick shot and put him back.

This one is odd, but it serves a purpose. We have an elderly cat who has bad joints so has trouble eating. I set out to create an adjustable tray so he didn’t have to bend down to eat. Here’s what I came up with. I made it tall enough to plan for the future (in case we end up getting a really large cat or a small dog someday in the future). Our cat can now comfortably eat while seated. The trays easily move up or down depending on the size of the bowl.

The inspiration for this: I had two Harbor Freight bar clamps in my shop, shown below, which I never use because I don’t like to use them for work holding. But the one thing I like about these is that the bottom clamp ratchet is very easy to move up and down. So I thought, what if I cut these clamps up and used the parts to make a cat feeder that could be adjusted?

This is the end result, with a touch of decorative cord wrapping. This was all made with wood scraps and it’s mostly poplar. I’m happy with how it came out and I believe it a one-of-kind design. I mean, really who is going to make something this weird?

Each tray is attached with four screws (and glued) to the aluminum clamp ratchets. I framed the trays so each has a lip so the cat can’t push the bowl off the edge.

I added bumper feet on the bottom of the stand to keep it off the ground a bit in case a water bowl is tipped. I made the top removable so each tray can be removed and cleaned. The tops are capped with scrap leather just to ensure we don’t cut ourselves on the cut aluminum edges. Each bar is set in the poplar base with deep mortises, glued, and screwed in. Also, I added wood inserts to the inner part of the bars for more sturdiness.

The top is shaped so it’s easy to lift off. I cut tiny mortises to fit these bits from the bar clamps and they just rest on top of the aluminum arms. I glued them in.

And here is the final. The apparatus is sized to fit nicely on a standard cat mat. I finished all the wood parts with three coats of Osmo TopOil High Solid.

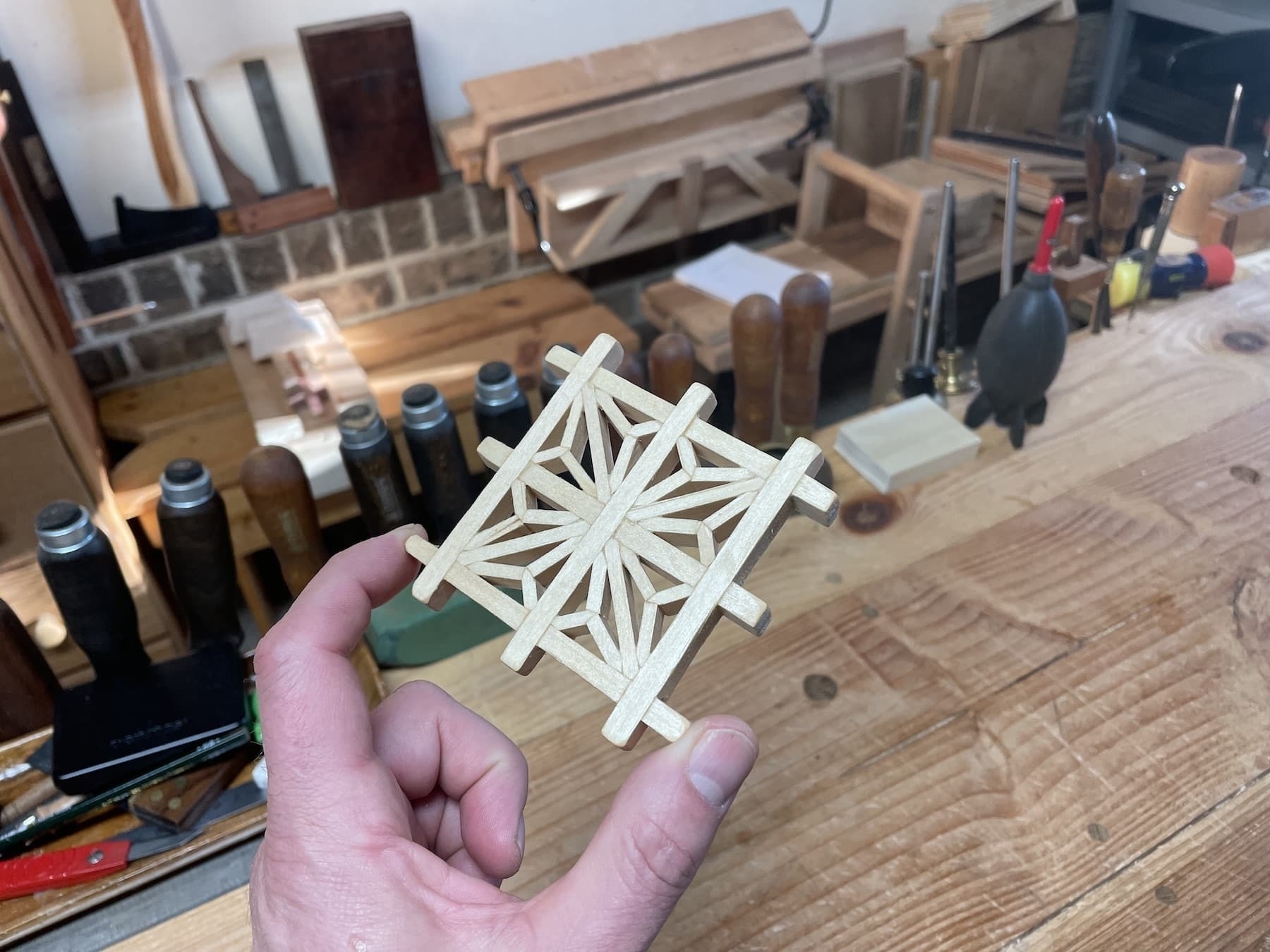

I decided to try my hand at making a small Kumiko ornament for the tree, as a first step in learning this process for later larger projects. This one took way more time than expected, because I needed to first create the jigs to cut tiny Kumiko strips. I figured out what I needed to do with an excellent book, Shoji and Kumiko Design: Book 1 The Basics by Desmond King, and very helpful YouTube videos from Adrian Preda. So I bought a big chunk of 5’‘W x 36’‘L x 1-1/16’’ basswood from Rockler and went to work. Here’s the finished piece.

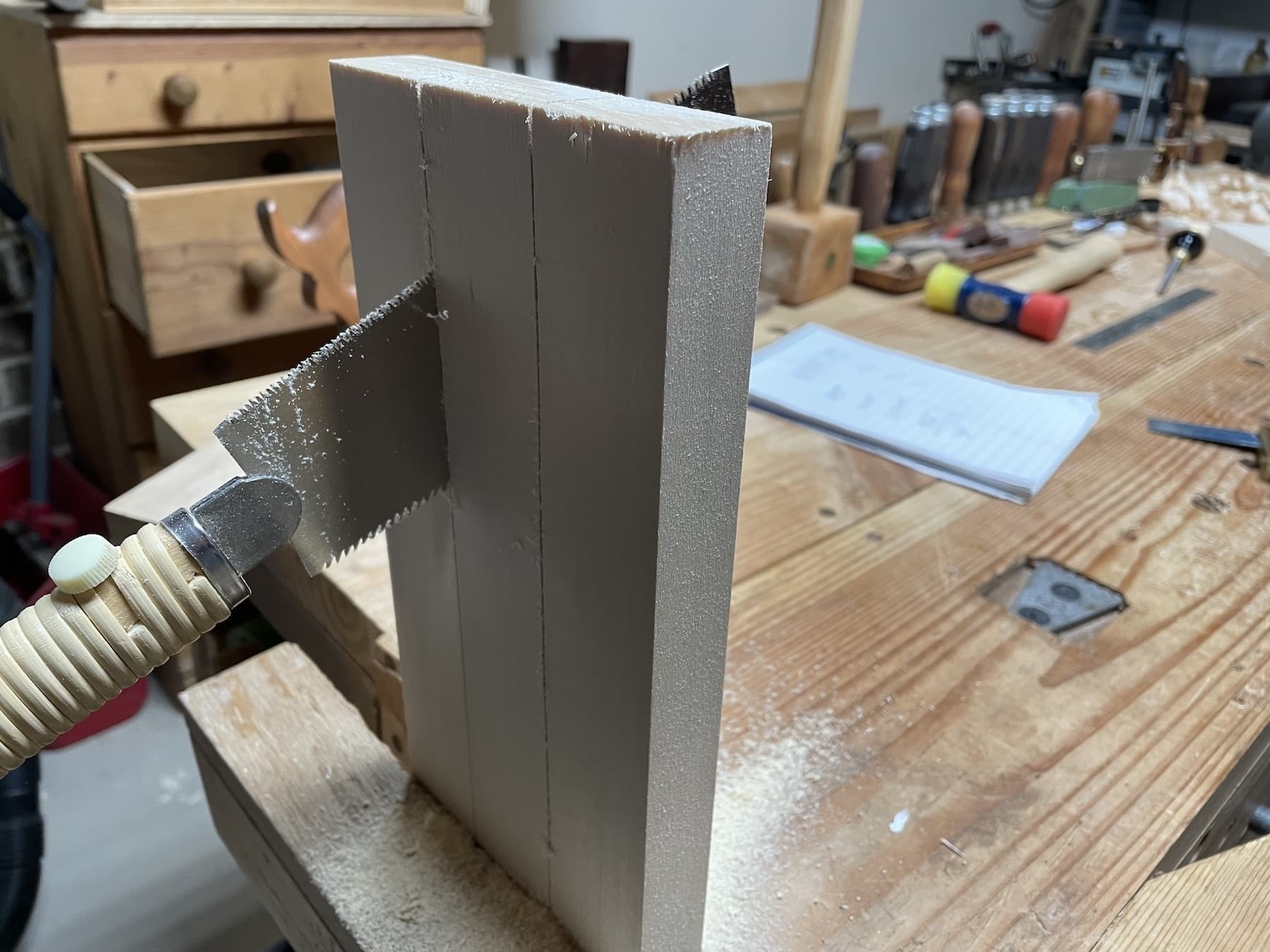

And here are the basic steps, starting with some pics of getting the basswood cut down to size. I started by cutting the board into thirds.

And then cutting those boards into thirds.

And then resawing all of those thirds.

I used two-sided tape to hold the wood while I cut the small strips out of the resulting boards, after planing them down.

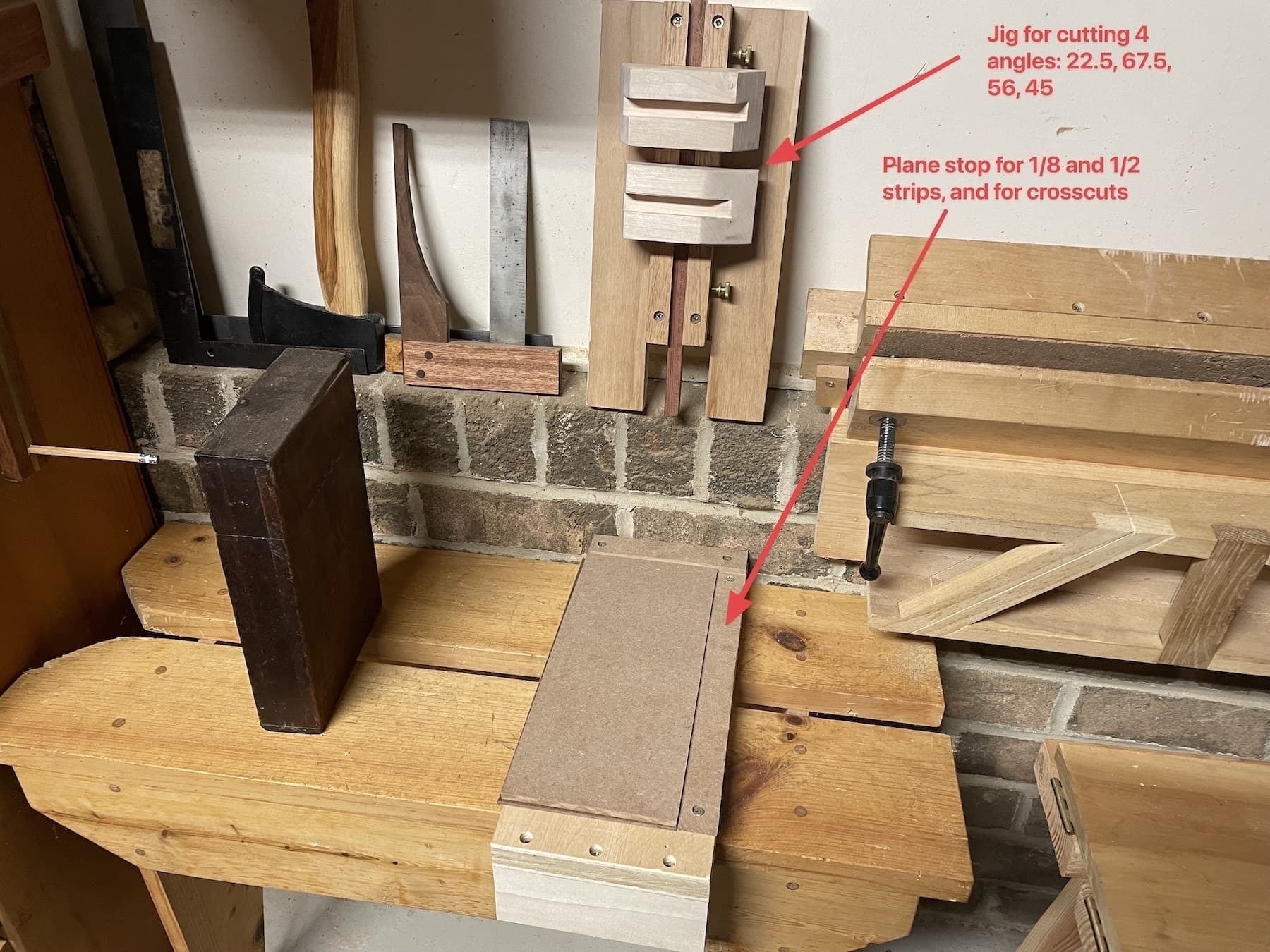

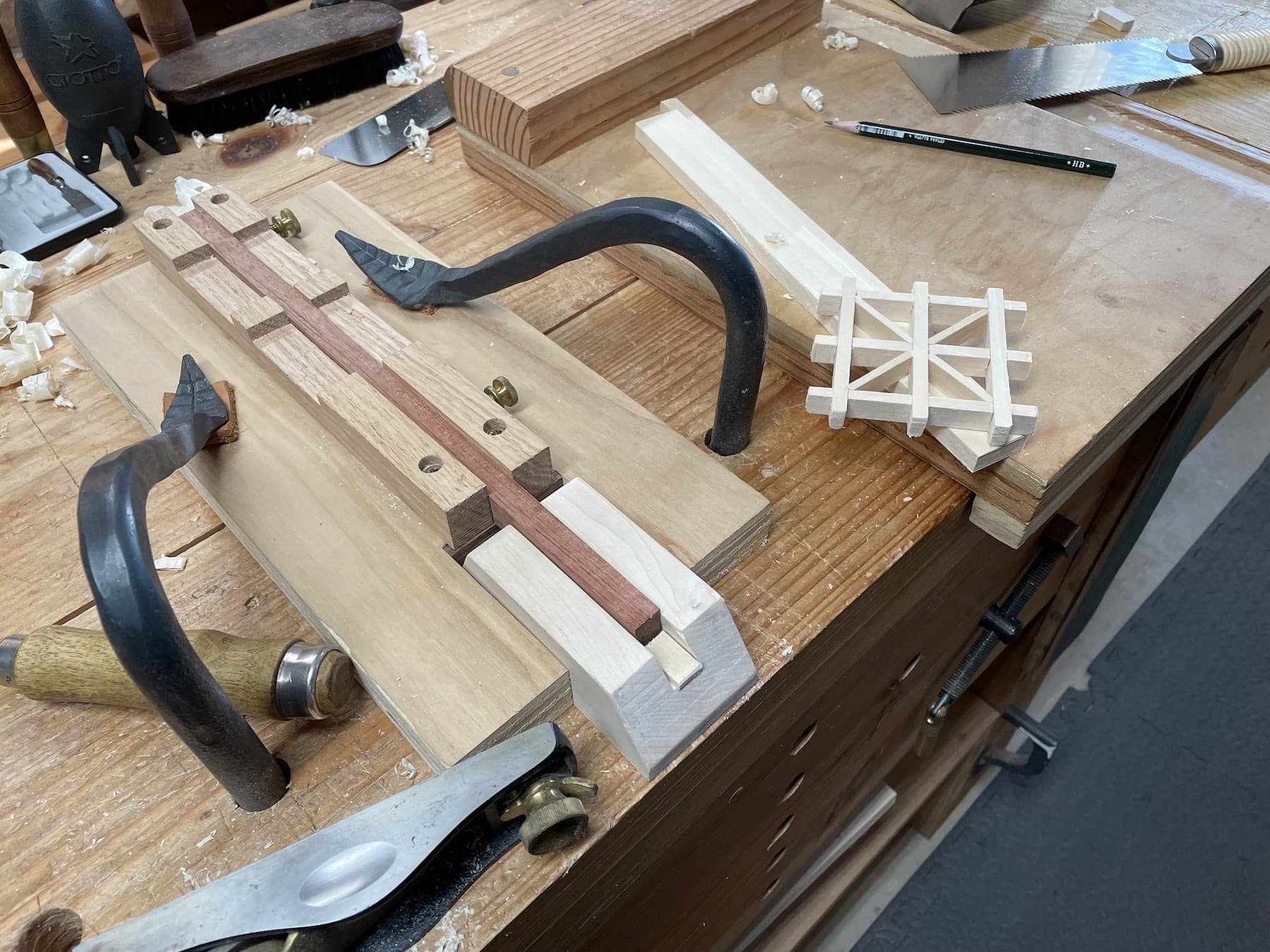

Here are the jigs I made, which took the most time in this project by far. The first one in the image below is for cutting the angles needed. I made this design up and I’m proud of it because it is all self-contained and can hang on a wall. You’ll see how it’s used shortly. The second jig is for planing the basswood down to uniform strips of 1/2" by 1/8"

Here’s the planing stop in action. The stop is 1/2" and two inserts are added as needed, one is 1/4" and one is 1/8". The side piece of MDF is used to cut the strips to length, after removing the inserts. So it does double duty.

Here’s how the angle-cutting jig works. The two short pieces of hard maple can be flipped around so each has two angles available. These fit into the jig with an adjustable stop for longer pieces. I hope to make larger Kumiko projects later on, so this gives flexibility. I can just cut new maple blocks if I need other angles to make other Kumiko patterns.

And here is my first Kumiko pattern (in the classic asa-no-ha shape). It is not perfect, but I’m happy how it turned out. I stuck it in the Christmas tree. Next year, I aim to batch produce a number of these for gifts. It was fun to learn how these work and was a challenge for hand tools only. Learning to do this with buttery basswood is a good way to go. I may next try one with walnut.

This is another going-away gift for a work colleague who left for another job. I’m incorporating a lapel pin in the project from my place of work, as I’ve found that cutting off the back pin part and insetting the small metal logo looks really nice. The box is poplar with a bubinga top and bottom. The gift is for someone who appreciates quality pencils, so this project was a great fit. The instructions for this box come from Renaissance Woodworking. This is a great, easy-to-do project. The pencils I bought for the box are Mitsubushi 9850. As an aside, I’ve found Mitsubishi 9800 pencils to be perfect for woodworking because the graphite is strong and makes dark lines.